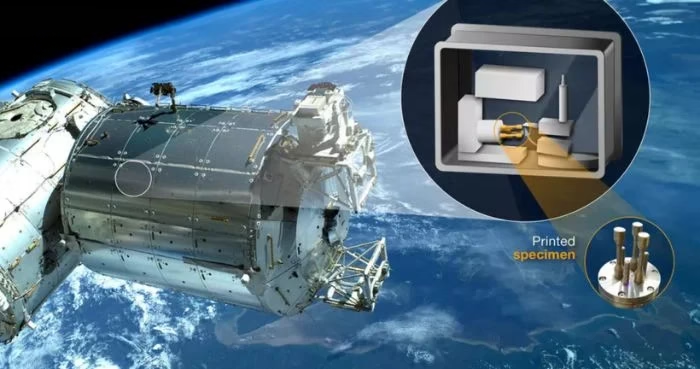

China has successfully carried out its first metal 3D printing experiment in space, marking a major milestone in its in-orbit manufacturing capabilities, the Chinese Academy of Sciences (CAS) announced on Saturday.

The experiment was performed by a retrievable scientific payload developed by the Institute of Mechanics under CAS. The payload was sent aboard the Lihong-1 Y1 suborbital vehicle, a commercial recoverable spacecraft built by CAS Space, which is also intended for space tourism missions.

The spacecraft completed its first test flight from the Jiuquan Satellite Launch Center in northwest China on January 12. After crossing the Kármán line — the boundary between Earth’s atmosphere and outer space — and reaching an altitude of around 120 kilometers, the payload autonomously produced metal parts in a microgravity environment.

According to CAS, the successful mission moves China’s space-based metal additive manufacturing from “ground-based research” to a new stage of “in-space engineering verification,” placing its technology at the global forefront.

The breakthrough is expected to strongly drive the development of China’s space manufacturing sector and act as a key enabler for future space infrastructure projects.

Researchers noted that metal additive manufacturing in space is far more complex than on Earth. The team overcame major technical challenges, including stable material transport and shaping under microgravity, full-process closed-loop control, and high-reliability coordination between the payload and launch vehicle.

The experiment concluded with a safe parachute-assisted landing of the payload capsule, which was swiftly recovered. Scientists have since obtained critical first-hand data on melt pool dynamics, material transport, solidification behavior, and the mechanical properties and precision of parts printed in space.

The Lihong-1 Y1 spacecraft has proven to be an effective and flexible test platform due to its low launch cost and adaptability. In addition to the metal 3D printer, the payload also carried rose seeds for an agricultural research project.

Deputy Chief Designer Wang Yingcheng said the team is developing the spacecraft for extensive reuse, with engineers currently testing crew life-support systems and highly reliable escape technologies. He added that these advances could enable low-cost suborbital scientific experiments and open the door to commercial space tourism.